Production courses

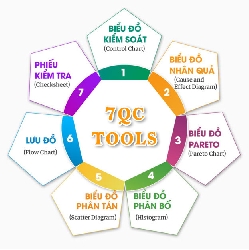

7 analysis statistical tools

Introduce

- Understand and apply some basic statistical tools to solve the problem of quality

- Correctly identifying anomalies, discovery of errors in products, the lack of control, and minimize their impact

- Know how to select and apply to the actual of production and services providing process of business to control the quality of products / processes

- Improve the effectiveness of the quality management system in enterprises using statistical tools to meet the requirements of ISO 9001:2008

5 Core Tools – ISO/TS 16949:2009

Introduce

- Understanding of SPC’s handbook (controlling process by statistical methods) with the concept of process control and process changes. Selecting the appropriate SPC tools for the analysis of the necessary process, interpreting the results of analysis and propose a business plan based on that interpretation.

- Understanding MSA (measurement system analysis), reference manuals and their application to the impact on the quality system, types of variation measurement system, and repeat Gage.

- Understand the FMEA’s application (mode and analysis effects) to reduce the risk from design stage through production all of processes.

- Understanding APQP Manual (Advanced Planning of product quality) and the links between the block diagram of the process, procedures, control plans, reporting specified requirements in the APQP’s reference guide of the quality management system of the company and reporting results.

- Verifying the design and manufacture products according to PPAP (Production Process Approval) and equivalent methods.

Total Productive Maintenance (TPM)

Objectives

- Reduced downtime due to breakdowns and converted products.

- Reduce speed loss (when devices can not operate at its optimal speed).

- Reduce idling time and stop unexpectedly because of abnormal operation of the sensor, work jams, ..

- Reduction of process defects caused by defective goods or cancel the need to recycle.

- Reduce waste testing.

Awareness ISO/TS 16949

Objectives

- Participants after completing this training will better understand the requirements of ISO / TS 16949:2009, as well as the ability to apply these requirements in the production activities at the request of customers such as Ford Motor Co., GM, Daimler Chrysler, Mercedes Benz, BMW, Fiat ...

- Consider the requirements of ISO / TS 16949:2009

- Equipped with the ability to specify the performance requirements needed to upgrade the system ISO 9001:2008, QS-9000 or ISO / TS 16949:1994 to ISO / TS 16949:2009

- Equipped with the ability to plan and manage the project implementation ISO / TS 16949:2009

- Equipped with the ability to identify the needed processes in the quality management system, order and interaction